By: Kris Phimsoutham

In recent years, traditional photography has been utilizing the technological advancements of digital photography to gain many benefits from it. Expanding materials limitations and enhancing image quality are a few examples of such benefits. I feel that the processes of alternative printing gains the most from this type of “hybrid photography”. Precise multi-negative registration and color separations, for example, are the most common tools used in multicolor gum printing. The color separation negatives are made from digital files. My experience with practicing hybrid photography happened almost accidentally. While experimenting with the cyanotype process, I’ve made several images using bubble jet photo paper. The results were quite unique and the quality of the images exceeded that of other cyanotype prints that I’ve made previously.

“Bubble Jet Cyanotype”

“Bubble Jet Cyanotype”

My “typical” cyanotype print

My “typical” cyanotype print textured cyanotype

textured cyanotype

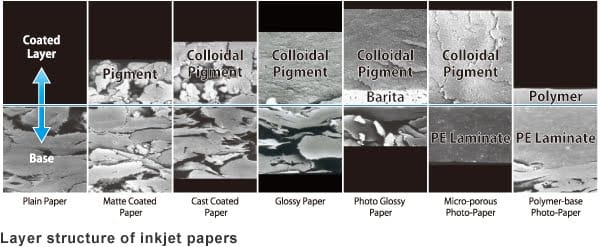

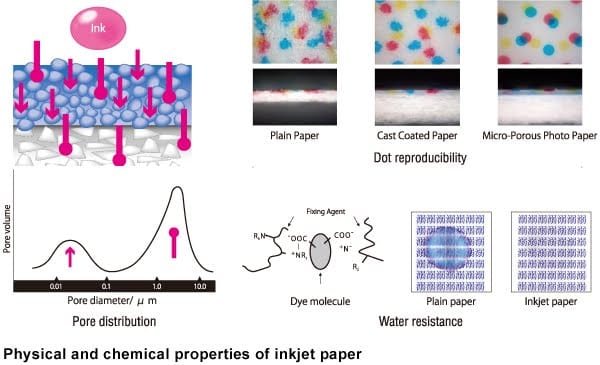

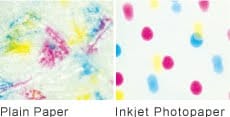

Various types of traditional art papers stretch and contract according to its ambient moisture level. If the paper is not properly stretched and sized, controlling the art medium on its surface will be difficult. Painters and printers encounter this problem often. Ink jet paper technology has developed methods to overcome this issue.

cross section illustration

cross section illustration

properties of paper illustration

properties of paper illustration

bleed control illustration

bleed control illustration

photos © Kris Phimsoutham

Reference illustrations from Mitsubishi Paper Mills Limited